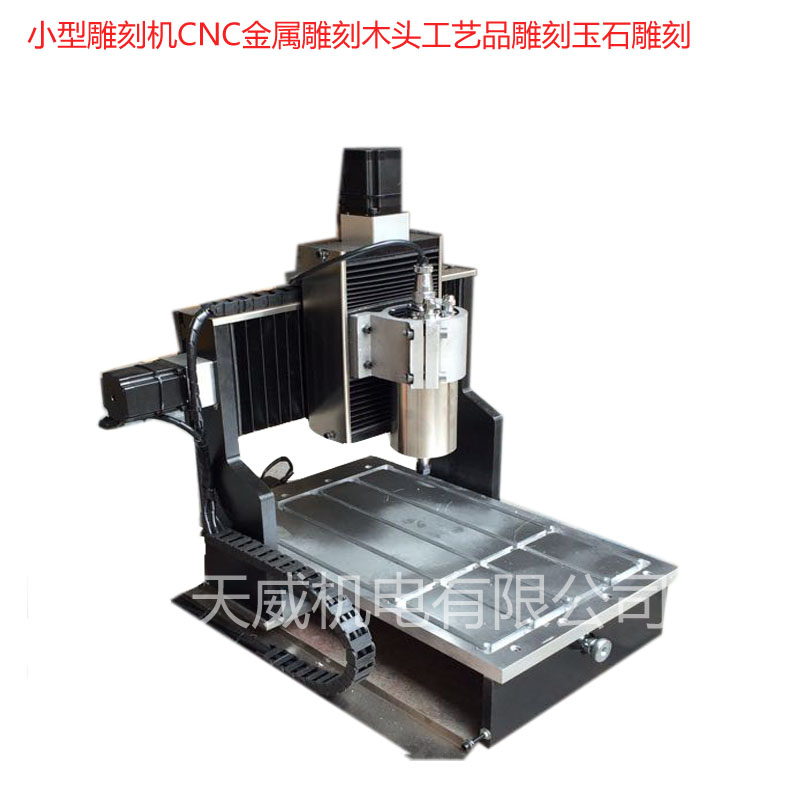

Device introduction: 1. The fuselage is firm and non-deformed, with good rigidity, high precision, reliable performance and durability. 2. Imported high-precision ball screw is adopted to ensure smooth movement and high precision of the machine tool. 3. The water-cooled spindle of well-known domestic brands is adopted, with low noise and large cutting force, which can ensure mass processing for a long time. 4. Good structural design of the whole machine to ensure long service life of the equipment. 5. The application of high-performance subdivision driver ensures the fast speed and high precision of the machine tool. 6. Electromechanical all-excellent design, selection of various electrical accessories, to minimize the failure rate.Application scope: Advertising, mold, woodworking building model, marking industry, teaching, enterprises and institutions, etc.Technical parameters:

|

Model |

6090 |

||

|

X/Y/Z axis travel |

600*900 * 100mm |

Maximum engraving speed |

3000mm/min |

|

Platform size |

700 * 1200mm |

Engraving instruction |

G code * u00 * mmg * plt |

|

Spindle power |

1.5kw |

Software Runtime Environment |

Windows98/2000/xp |

|

Spindle speed |

24000rmp∕min |

Drive |

Imported high-precision lead screw |

|

Power supply |

AC220V/50Hz |

Guide Rail |

Imported high-precision guide rail |

|

Machining Accuracy |

0.05mm |

Control system |

Weihong (optional handle) |

|

Maximum operating speed |

7500mm/min |

Bed body structure |

Cast aluminum or welded profile structure |